We are partner for the very bests

Processes

Strojmetal is an expert on the production of aluminum chassis parts and industry solutions. We are able to customize our production precisely to the customer requirements. Thank to our know-how, we can offer the best and most effective solution to the customer.

We provide a comprehensive collaboration, starting from product development up to its delivery. This process is set in such a way so it can always be modified flexibly according to the customer needs.

Pre-development

We offer our know-how to the customers already in the new product design stage.

Development

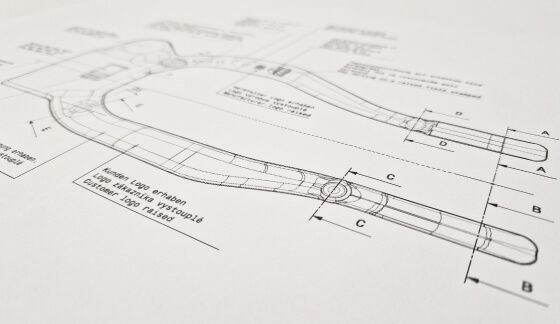

Based on customer demands, we design and manufacture a 3D model of the product that we test. Once the results correspond to the customer requirements, the product is released for further processing as of design and technology. We offer development in the machining stage as well, especially regarding the choice of suitable tools. In the field of development, we provide two types of orders, and thus “build to print,” or “build to specification.”

Desing and technology

Thank to our experienced team of designers and developers, we can always offer a precise and maximally effective solution.

Tool manufacturing technology

Due to modern CNC milling machines and other equipment, we are able to manufacture top quality tools (dies).

Forging

Mass production is done on automated and robotized forging line. These mechanisms are operated by specially trained employees of a high level of expertise.

Machining

Machining is processed on highly modern automated robotized machining centers. These centers guarantee the precision of high quality of our products.

Automated assembly

A part of machining centers actions is also the assembly of dampers into our products. The assembly is fully automated which guarantees a high precision of the final product

Tech center

Modern Tech center arranges for complete industrial testing and perfect control of all our products. We conduct static and dynamic mechanical testing, metallography, corrosion tests, and surface analyses be means of light microscope.

Shipping and logistics

We ship in 14 countries worldwide and due to an advanced planning system, we are able to ensure product deliveries as per customer needs.

Quality

The quality management in Strojmetal Aluminium Forging is based on EN ISO 9001 and IATF 16949. Continuous customer testing and audits always guarantee a high-quality standard. Consistence creates one of the highest business targets of Strojmetal Aluminium Forging.